Nylon Yarn Manufacturer

Product Introduction

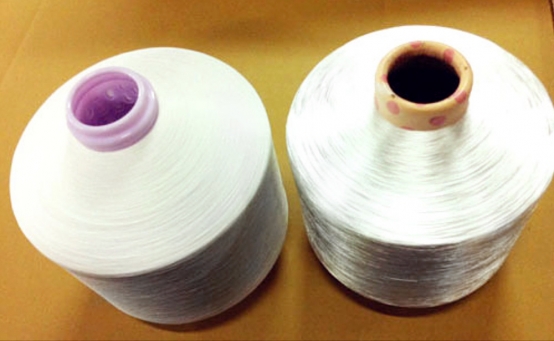

The production of Herng Fa nylon yarns takes shape from the raw material of synthetic origin that we purchase only from the best suppliers, guaranteeing the yarn of Nylon 6 and Nylon 66.

As a reliable nylon yarn manufacturer, Herng Fa has 60 sets of twisted yarn machines providing the head twist processing business to reduce the cost of products. With decades of experience in the textile industry, we specialize in producing high-quality nylon yarn, catering to various applications and industries.

What is Nylon Yarn?

Nylon yarn is also known as polyamide yarn (PA). Nylon yarn includes Nylon 6 yarn (PA6) and Nylon 66 yarn (PA66).

It is a synthetic material that can be engineered to resemble the look and feel of many natural fibers. Originally created as a substitute for expensive materials, nylon yarn offers several advantages over natural fibers, such as silk. It is slightly stretchy, strong, has high abrasion resistance, and is generally more affordable.

Key Features

- Stretchy and Strong: Nylon yarn provides excellent elasticity and strength, making it suitable for a wide range of applications.

- High Abrasion Resistance: The yarn is highly resistant to wear and tear, ensuring durability in various uses.

- Cost-Effective: Generally cheaper than natural fiber yarns, nylon yarn offers a budget-friendly alternative without compromising on quality.

Applications

Nylon yarn can be used in place of natural fiber yarns to create a variety of products, including:

- Velcro Straps

- Underwear Straps

- Ribbons

- Vamps

- Cool Sensation Clothing

Specifications of Nylon 6 and Nylon 66 Yarn

| Yarn Type | Luster | Denier Range | Fiber |

|---|---|---|---|

| FDY (Fully Drawn Yarn) |

Bright or semi-dull depending on the finish | 20D ~ 6000D | Continuous filament |

| POY (Partially Oriented Yarn) |

Semi-dull or semi-bright | Continuous filament | |

| HOY (High Oriented Yarn) |

Typically semi-dull | Continuous filament | |

| DTY (Draw Textured Yarn) |

Usually semi-dull or semi-bright | Drawn and texturized filament | |

| ATY (Air Textured Yarn) |

Generally dull to semi-dull | Air-texturized filament |

Nylon Yarn Twisting Process

In the modern textile industry, the technology for twisting nylon yarn is continually evolving, providing high-performance nylon threads for various applications. This advanced processing technique enhances the characteristics of nylon fibers, making them well-suited to diverse market demands.

- Selective Twisting Process: Multiple individual nylon filaments are combined into a stronger and more stable yarn. This enhances the yarn’s strength and durability, allowing it to withstand various environmental conditions and application scenarios.

The benefits of nylon yarn twisting extend beyond strength, wear resistance, and elasticity. It also facilitates easier integration with other materials, expanding its application scope. Nylon yarn finds widespread use in various products, including clothing, home textiles, and industrial applications.

Get a Quote for Nylon Yarn

Nylon yarn twisting is an advanced technique that enhances nylon yarn performance, providing efficient and reliable material solutions across different industries. Continuous innovation and technological improvements will further broaden the prospects for nylon yarn applications, meeting ever-changing market needs.

For more information or to place an order, please contact Herng Fa nylon yarn manufacturer.